The Monastic Recipe

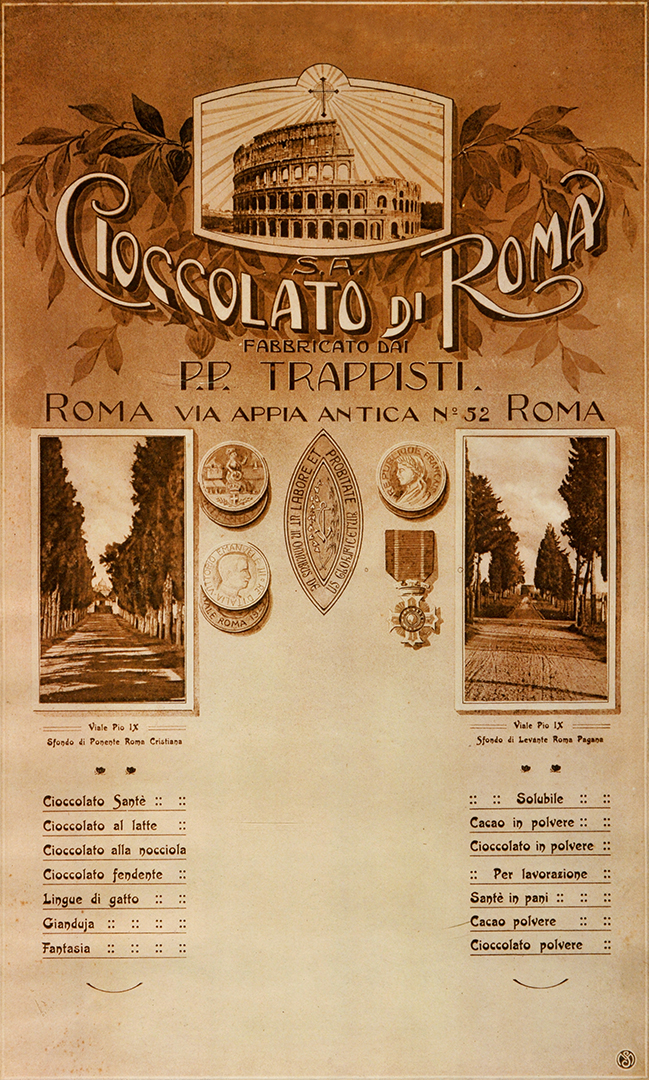

The Monastic Recipe The old monastic recipe of Il Cioccolato dei Trappisti dates back to the Eighteenth century. Dutch Trappist Monks who moved to Rome following papa Leone XIII’s will, started the first artisanal production of the Chocolate. They settled their first studio in 1880 near the San Callisto Catacombs and started at that time the production of the first chocolate of Rome. Il Cioccolato dei Trappisti is still processed today, after almost 140 years, according to the same recipe, handed down through craftsmanship from generation to generation, a factor that establishes its absolute uniqueness and peculiarity. It is prepared with high-quality ingredients carefully chosen, like the famous Tonda Gentile Romana DOP hazelnuts, and still processed today with antique equipment (end of the Eighteenth, first half of the Nineteenth century) and hand shaped.

The phases of production

Phase 1

The Dough

We start processing our chocolate, kneading the raw material: the cacao paste, gluten free powdered sugar and, according to the type of chocolate, powdered milk. The dough takes place in a millstone.

Phase 2

Refining

The dough is refined, grounded to a dimension of few microns through five cylinders.

Phase 3

The conching process

The powder obtained, together with cacao butter and other natural ingredients such as vanilla and soy lecithin is poured in the stirring tank and “conched” at controlled temperature for 30 up to 48 hours. The blend is a melt-in-the-mouth chocolate ready to be hand-modeled.

Phase 4 – Tempering

The chocolate during this phase is at first cooled down and then warmed up at different temperatures, following the old recipe recommendations, according to the different types of chocolate processed, so as to have molecules properly crystallized.

Phase 5

Moulding

The chocolate mass obtained after the conching process and the tempering is now hand-modeled into moulds. That means that every chocolate bar is somehow unique, and for what concerns hazelnuts bars, these too are handmade so that whole hazelnuts are homogeneously spread.

Phase 6

Cooling

In the last phase the hand-modeled chocolate bars are cooled down in the

refrigerators. The bars get their distinctive texture and fragrance.